Vacuum encapsulating systems

High-precision volumetric metering system ensures that products continue improving

The volumetric metering system contributes to high-precision metering since it is not greatly affected by changes in liquid viscosity.

The discharging liquid must be completely degassed before vacuum potting in customers products. Our original design is used in every section of the Vacuum encapsulating systems to degas the resins in tanks and ensure that the liquid path is sealed.

Naka Liquid Control produces systems for a variety of

applications to meet customers specific requirements.

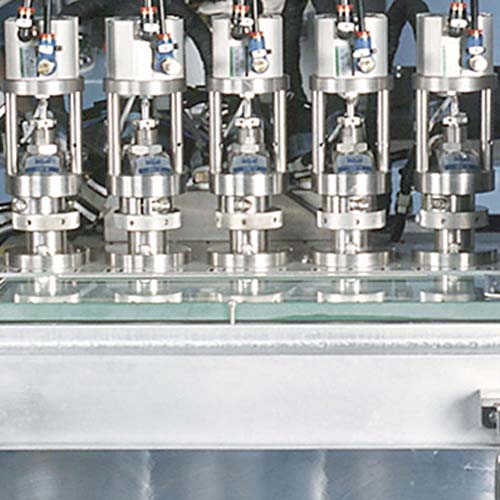

8-outlet simultaneous dispensing

3-outlet simultaneous dispensing

5-outlet simultaneous dispensing

3-outlet simultaneous dispensing

12-outlet simultaneous dispensing

Component names and functions

We produce various Vacuum encapsulating systemss ranging from simplified, manually operated, single-output systems to large, automated, multi-output systems. All of our systems are designed and constructed according to customers requirements, and are the optimal Vacuum encapsulating systemss for producing high-quality products.

Tanks

Resin in the tank is degassed at a high vacuum level. A stirrer or heater is attached to facilitate degassing, depending on the viscosity of the resins employed. With durability and safety in mind, Naka Liquid Control employs closed tanks with high reliability.

Resin in the tank is degassed at a high vacuum level. A stirrer or heater is attached to facilitate degassing, depending on the viscosity of the resins employed. With durability and safety in mind, Naka Liquid Control employs closed tanks with high reliability.

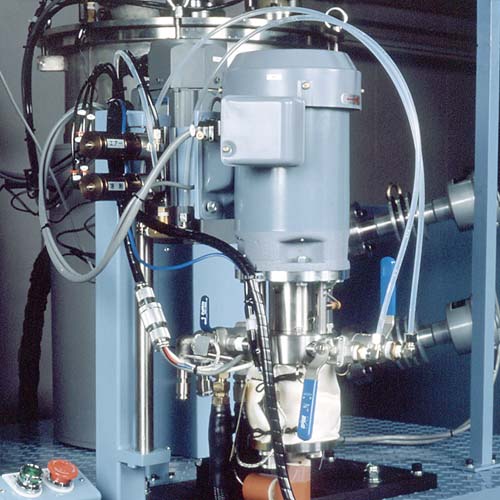

Metering pumps

The pumps meter the resin with high precision. Since the resin is stirred or heated for vacuum potting, changes in its viscosity occur. Naka Liquid Control has chosen a volumetric metering system (posi-load plunger pump) capable of metering with high precision without regard to resin viscosity.

The pumps meter the resin with high precision. Since the resin is stirred or heated for vacuum potting, changes in its viscosity occur. Naka Liquid Control has chosen a volumetric metering system (posi-load plunger pump) capable of metering with high precision without regard to resin viscosity.

Mixers

The mixer combines two types of resin. Either an electric rotary mixer or motionless (static) mixer is selected according to the resin viscosity and discharge volume. Mixers designed to prevent the suction of outside air are available specifically for vacuum potting.

The mixer combines two types of resin. Either an electric rotary mixer or motionless (static) mixer is selected according to the resin viscosity and discharge volume. Mixers designed to prevent the suction of outside air are available specifically for vacuum potting.

Vacuum chambers

A vacuum is maintained in the chamber to prevent the inclusion of any air in the resin during potting. The vacuum chamber must be capable of closing itself at levels commensurate with the vacuum level reached. Naka Liquid Control produces manually operated or automatic vacuum chambers with closing capability and a variety of pallets, heating or curing ovens, conveyors, and the like to meet customers specific requirements.

A vacuum is maintained in the chamber to prevent the inclusion of any air in the resin during potting. The vacuum chamber must be capable of closing itself at levels commensurate with the vacuum level reached. Naka Liquid Control produces manually operated or automatic vacuum chambers with closing capability and a variety of pallets, heating or curing ovens, conveyors, and the like to meet customers specific requirements.

Shut-off valves

Vacuum potting involves placing products in the vacuum chamber, evacuating, and then discharging the resin(s) via output valves. Shut-off valves developed by Naka Liquid Control are designed to discharge liquid specifically for vacuum potting and constructed to minimize the quantity of liquid retained in the output nozzles, thus eliminating dripping.

Vacuum potting involves placing products in the vacuum chamber, evacuating, and then discharging the resin(s) via output valves. Shut-off valves developed by Naka Liquid Control are designed to discharge liquid specifically for vacuum potting and constructed to minimize the quantity of liquid retained in the output nozzles, thus eliminating dripping.